Oil-immersed non-partial discharge transformer

Oil-immersed non-partial discharge transformer

Our strengths:

The flux density is less than 1.45T.

The winding structure is improved and the impulse voltage distribution is good.

Reasonable selection can improve the distribution of field intensity and effectively reduce the amount of partial discharge.

It meets the requirement of low partial discharge measurement.

The module has bad structure and occupies less space.

Low impedance voltage, low no-load loss.

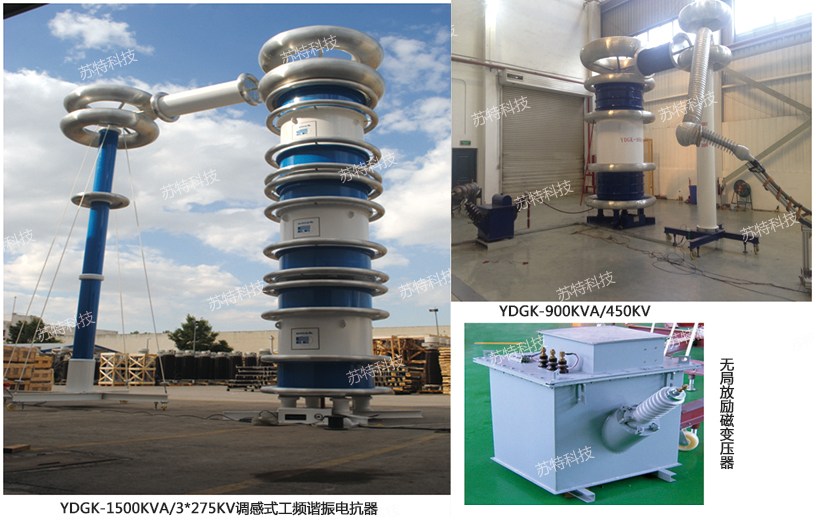

Sketch:

The power frequency test transformer system can produce a continuously adjustable power frequency AC test voltage. It is used for power frequency withstanding, partial discharge detection and other scientific research of GIS high voltage switch, cable and cable accessories, transformer, power transformer, high voltage circuit breaker, capacitor bushing and other electrical components.

Insulator type:

It can be composed of single pole and series pole, modular structure, easy to overlay. The insulating cylinder is made of epoxy reinforced glass fiber, and oil is injected into the insulating cylinder. This structure is suitable for indoor use, usually operated in short time under rated current.

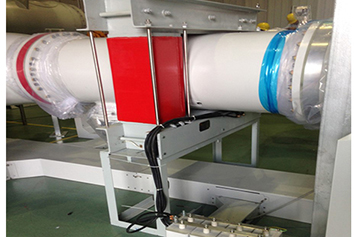

Metal iron enclosure type:

As an independent test transformer, the enclosure is grounded. The test transformer saves space because it can be placed on walls or even outdoors and guided to the laboratory by bushing. Metal-enclosed transformers can also be used in series or in parallel. This type of transformer has larger capacity than the insulating barrel type, can meet the high voltage pollution test, test current is large, and can operate continuously.

Design Description:

1. There are two commonly used structures of test transformer: the upper column is core column, the lower column and the left column are yoke column, and the upper column is equipped with high-voltage coil (progressive coil) and low-voltage coil; while the large capacity, high voltage, low impedance and low partial discharge capacity, another structure is adopted, that is, the upper and lower column are core column, the left and right column are yoke column, and the upper and lower core column are installed respectively. There are high voltage coils (cascade coils) and low voltage coils, which can be used in series and parallel.

2. Flux density < 1.45T;

3. Improve the winding structure and make it have good characteristics of impulse voltage distribution.

4. Reasonable selection can improve the distribution of field intensity and effectively reduce the amount of partial discharge.

5. Reduce the height of the area occupied by the unbalanced ampere turn of the coil and reduce the axial electrodynamic force of the coil.

Main technical features:

1. To meet the requirement of low partial discharge measurement;

2. The module has bad structure and occupies little space.

3. Low impedance, low no-load loss.

English

English  Chinese

Chinese